Subsea Kills

So you elected to do subsea then did you? That means a couple of extra chapters to plough through and this is the first one. But don’t panic it’s not going to be painful. Well not too painful anyway.

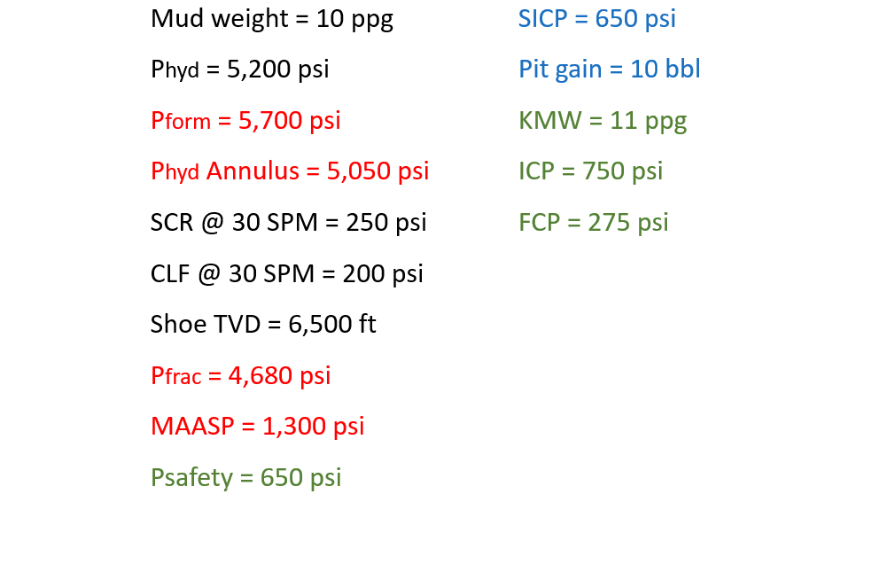

We’re still on the same well as the surface stack kills earlier in this manual:

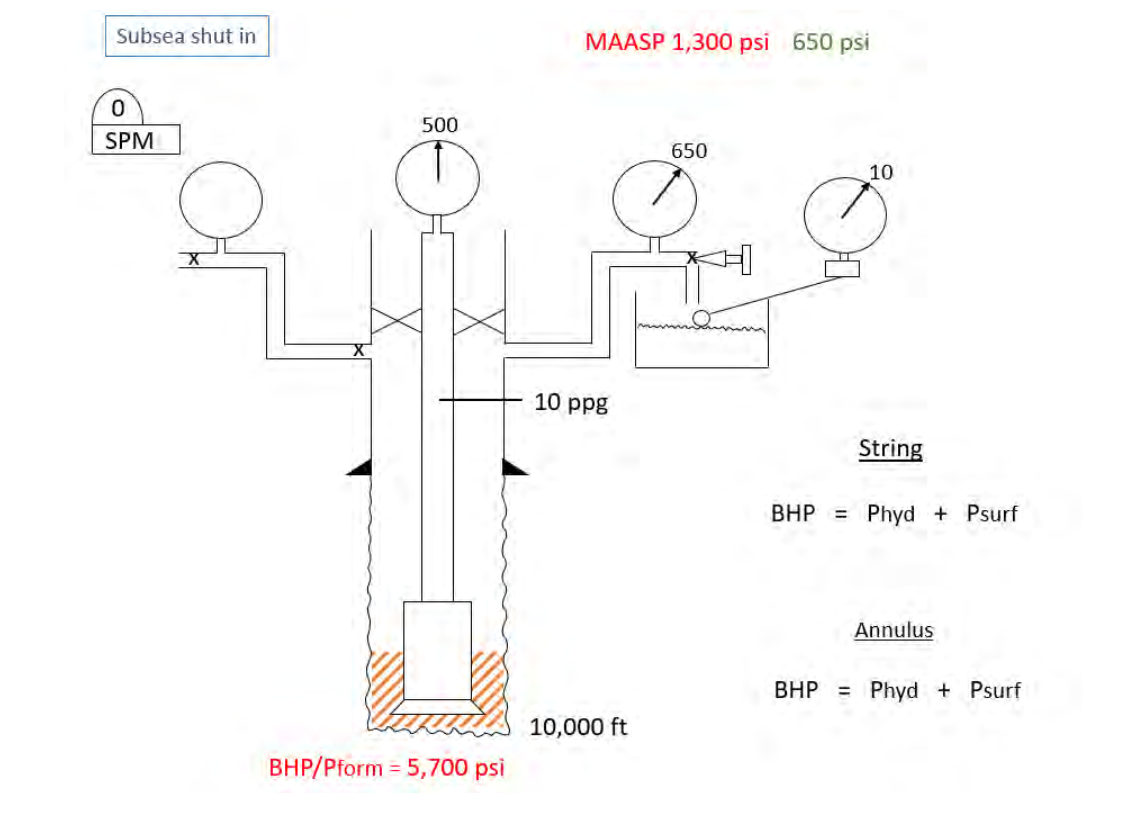

And visually it looks like this:

With the BOP on the seabed we must circulate up through the choke line from the stack to the rig and as we already know we have Choke Line Friction to take into consideration. APL is ignored this week, but CLF is too big to ignore. There are two times when CLF needs to be accounted for.

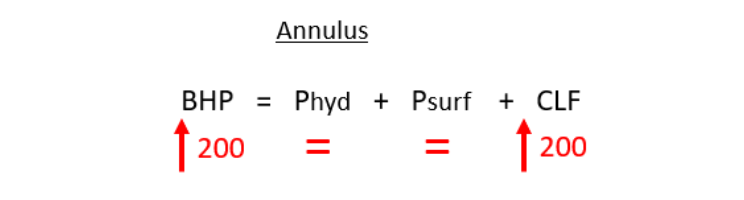

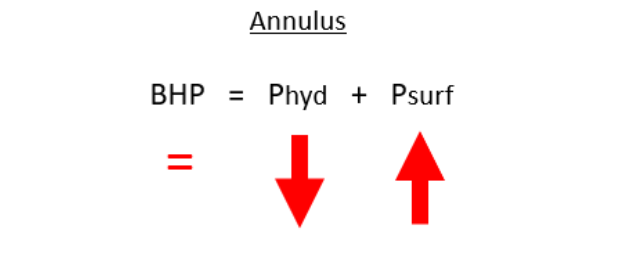

The obvious one is on a start up/shut down. We know CLF acts down the choke line when we are circulating up the choke line (circulating pressure ALWAYS acts opposite to the direction of travel). If we ignore CLF when starting the pump by holding casing pressure constant then we will increase BHP by an amount equal to CLF:

We already know that there is no measurable change to the hydrostatic pressure in the annulus on a pump start up meaning the only value we can change to compensate for CLF is casing pressure – we need to let it fall by an amount equal to CFL when increasing the pump speed:

When starting a kill, subsea stack, we must allow casing pressure to fall from Original SICP to Initial Dynamic Casing Pressure – the last calculation on page two of our subsea kill sheet - SICP minus CLF.

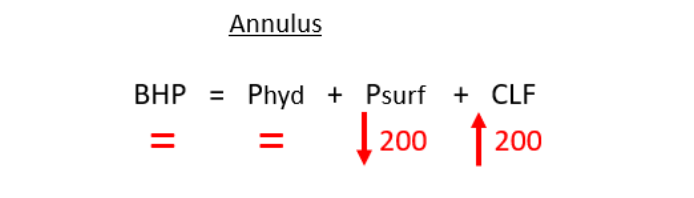

When shutting down a kill we must allow casing pressure to increase by CLF or we will lose BHP.

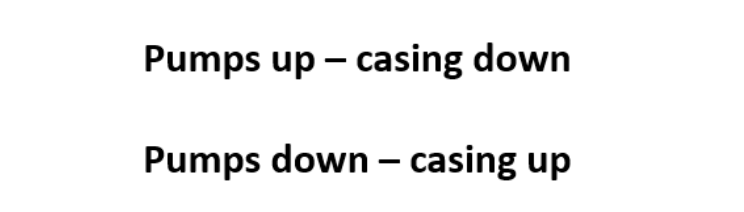

Simply put we get:

Whatever way the pump speed is going the casing pressure gauge must go the opposite way – if you are increasing your pump speed you must decrease casing pressure by an amount equal to CLF and if you are decreasing your pump speed you must increase casing pressure by an amount equal to CLF.

And there is every CLF start up/shut down question you are ever likely to get answered!

Of course we could use our static kill line gauge to compensate for CLF on a start up/shut down seeing as there is no circulating pressure in the kill line. Much easier. If we can use one.

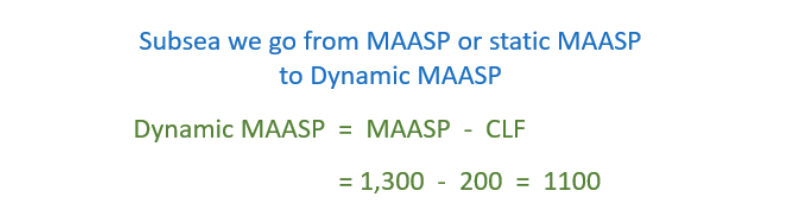

We must also consider how CLF impacts MAASP. MAASP is the total amount of pressure, above hydrostatic, that we can apply to the shoe without risking damage to the shoe. When circulating up the choke line we know that CLF is acting down the annulus and that includes onto the shoe. Subsea we go from regular MAASP to Dynamic MAASP – MAASP minus CLF. Same thing as dynamic casing pressure on the previous page if you think about it.

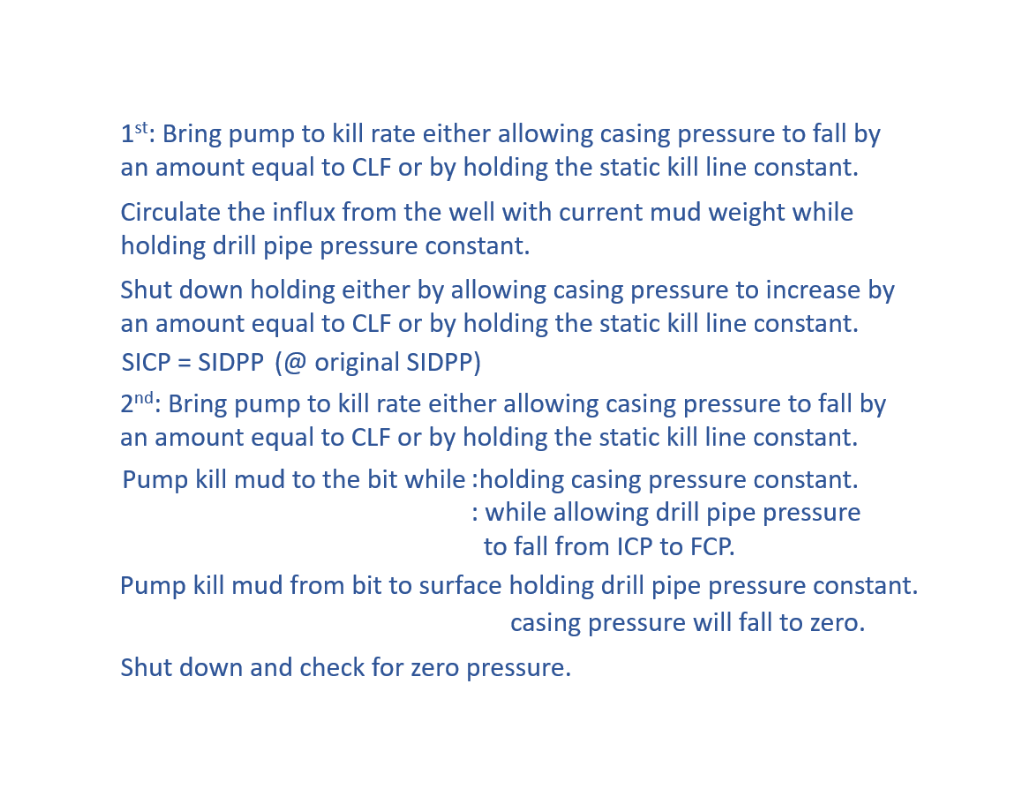

Once you are into the kill then the procedure is the same as it is for surface stack, and we expect to see the same things happen during the kill. Almost. Looking at the drillers method we get:

Once you are into the kill then the procedure is the same as it is for surface stack, and we expect to see the same things happen during the kill. Almost.

As the influx is circulated up the annulus pit volume and surface casing pressure both increase. Pressures in the annulus act according to IDS. What we also get subsea is a big message telling us gas is entering the choke line. When gas fills the choke line we get a rapid loss of hydrostatic from the choke line (gas weighs less than mud) which we see as a rapid increase in surface casing pressure.

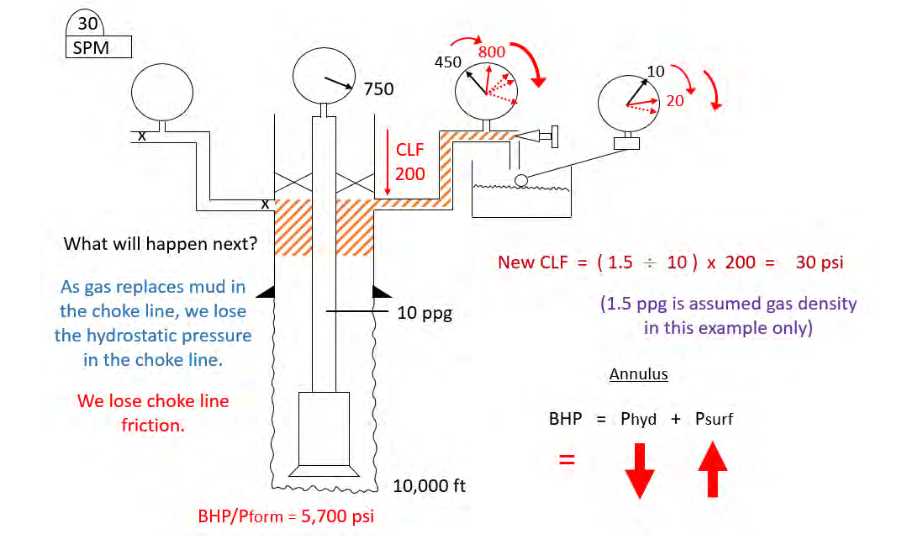

As gas fills the choke line we lose mud and therefore hydrostatic pressure from the choke line. We also lose CLF (as shown below) so if the choke operator does nothing then BHP will reduce and this could cause the well to go underbalance and let another kick in. The choke operator needs to start closing the choke when gas starts to fill the choke line to maintain the correct BHP.

Similarly once mud starts to replace gas in the choke line then the choke operator needs to start opening the choke again as CLF is restored - BHP will increase if no action is taken.

Once you are into the kill then the procedure is the same as it is for surface stack, and we expect to see the same things happen during the kill. Almost.

Regardless of the kill method we are told to hold final circulating pressure constant as kill mud is pumped up the annulus to surface. When kill mud reaches surface the choke will be fully open, casing pressure will be reading zero and we should still have FCP on the drill pipe gauge when pumping.

Subsea we will not be able to do this. Why not? Yep our old friend choke line friction again.

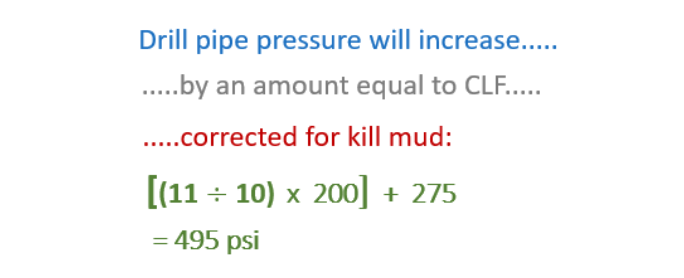

Subsea the choke will be fully open with casing pressure reading zero and FCP on the drill pipe gauge before kill mud returns at surface. As we continue to pump kill mud up the annulus, and in particular up the choke line, pump pressure (drill pipe pressure, standpipe pressure, circulating pressure whatever name you prefer) will increase due to the pump having to work harder.

Drill pipe pressure will increase by an amount equal to choke line friction corrected for kill mud weight – adjusted choke line friction from our kill sheet.

Once you are into the kill then the procedure is the same as it is for surface stack, and we expect to see the same things happen during the kill. Almost. And now you know when not.

With kill mud back at surface and the kill shut down the well should be dead - both SIDPP & SICP should be zero.

Subsea we still have two final issues to deal with. There will still be original mud in the riser and there is the potential for gas to be trapped between the BOP we have closed and the choke line we were circulating through. Company procedures will tell you how to proceed and should always be followed as they will be specific to your rig.

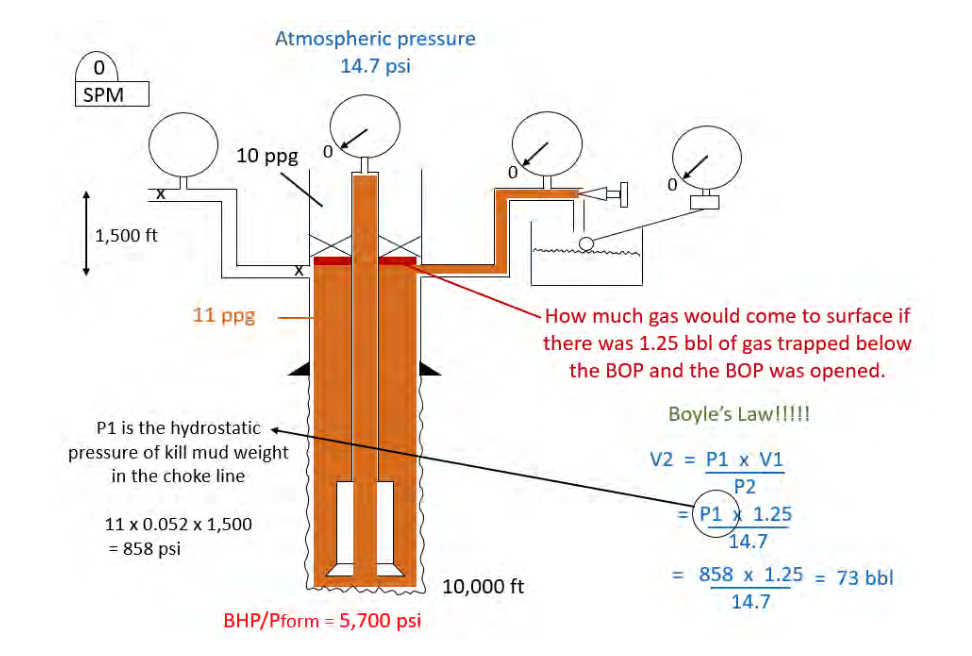

If you do not deal with the trapped gas and open the BOP then the trapped gas will come to surface, expanding rapidly as it does, and you could evacuate the riser contents:

It is important to deal with the trapped gas as per your company procedures & rig specific equipment.

If you have a boost line on your riser then that can be used to circulate the riser to kill mud. If you have a gas bleed line (or gas vent line) on your BOP stack then that can be used to circulate out the trapped gas.

If you have neither then you potentially need to look at using the existing riser contents to U-tube the trapped gas out through the choke.

This will be done in stages along the lines of:

- Isolate the well by closing a set of rams below your choke line.

- De-pressurise the gas by circulating light fluid (base fluid) into the choke line.

- Open the BOP and allow the mud in the riser to U-tube into the choke line flushing the gas up the choke line and out through the choke.

- Displace the riser and choke line to kill mud.